|

Building Owner

|

Hongkong Land Limited

|

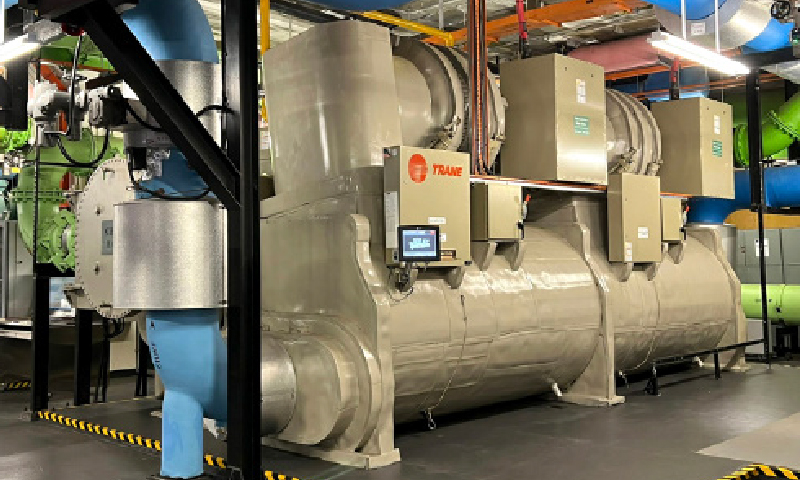

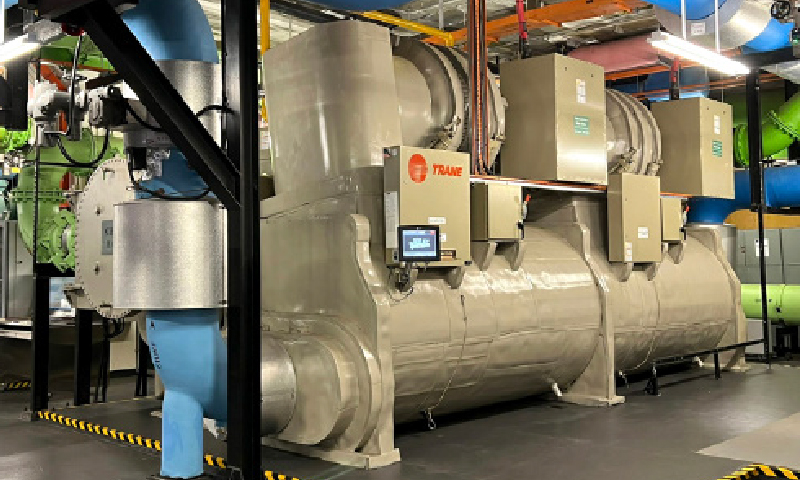

Replacement of more efficient chiller

Installation of smart energy management platform for data collection and visualisation, performance monitoring and evaluation, demand control and efficiency optimisation

| | Building/Project Name |

Exchange Square

| | Systems |

HVAC - Waterside Air Conditioning System

Building Automation /Management System

Smart control Platform

| | Building Types |

Commercial - Office

|

Description of the building:

- Grade A Commercial Buildings for a prestigious, globally oriented, 24-hour business complex.

- 52 levels for One Exchange Square and 51 levels for Two Exchange Square comprising of offices, retail, and F&B outlets.

- Fully air-conditioned with direct sea water-cooled central chilled water system with primary and secondary chilled water pumping system.

- Air handling unit (AHU) and Fan-coil units (FCU) for offices, retail, and F&B outlets with pre-treated fresh air.

Retrofitted initiative:

- Centralised chilled water plant:

Two 3,000Tons existing sea water-cooled chillers were replaced by two new 1000Tons and one 2000Tons direct sea water-cooled chillers. New primary pumps were also replaced for new chillers. For Chiller-1A and 1B, two new primary pumps are installed for chilled water and two new heating water pumps were installed for heating water system. For Chiller-2, two new primary pumps were installed. At the discharge side of each chiller, constant flow control valve was installed for automatic flow rate control of chilled water passing through each chiller. A decoupling chilled water system was arranged for the central chiller plant. It consists of constant water flow through each chiller evaporator and variable flow secondary water distribution system.

- Chilled water plant control:

DDC control system is provided for fully automatic control, energy optimisation control, monitoring, supervision and data logging for chilled water plant operation. The building load requirement is predicted by the DDC control system based on the loading profile in the past years. The predicted building load is analysed to determine the optimum configuration of the chiller plant.

- Implementation of JEDI (Jardine Engineering Digital Insight):

This further enables system fault detection, chiller optimisation and real-time energy dashboards.

|

|

|

Observed benefits other than energy saving:

- Lower noise level since the new chillers adapt multiple stage of compression which operate exceptionally quieter.

- Heat recovery at condenser side of chiller to eliminate additional heating equipment and reduce condensing water (seawater) provision.

- Diversity in chiller capacity and chiller types to cater for optimisation based on cooling loading.

- Enhanced building load prediction system with optimised control logic to allow the system to determine the most optimal combination of equipment to suit the predicted building demand.

General observations of the retrofitting project:

- Before the project, heating water was generated by the old chiller which can either operate in cooling mode or heating mode. We applied heat recovery operation in this project since the buildings require simultaneous cooling and heating, i.e. the base building cooling demand is high even in winter. This is the most critical consideration to adapt this energy saving operation.

- All chiller units are now being fitted with an electromagnetic clamp-on device installed on the exterior of condensing seawater pipes. This greatly hinders growth of microorganisms which adversely impact the heat transfer at the condensers.

Other information:

| Cost |

Saving |

| Total cost: |

over HKD 60 million (2016) |

Savings/year breakdown: |

>23% saving on annual water side energy consumption

>3.4 MWh saving per year compared to maintenance cost of aged chillers >HKD 6 million |

| Cost breakdown: |

Mechanical and Electrical work over HKD 15 million

Chiller Supply over HKD 30 million

Major Equipment Supply over HKD 15 million |

| Payback: |

(HKD 60 million – HKD 6 million) / HKD 4.9 million = 9.15 years |

| Name of the consultant and contractor |

Consultant:

J. Roger Preston Ltd.

Contractor:

The Jardine Engineering Corp., Ltd. |

| |

|

Replacement of more efficient chiller

Installation of smart energy management platform for data collection and visualisation, performance monitoring and evaluation, demand control and efficiency optimisation

|

|

|

Building Owner

|

Hongkong Land Limited

| | Building/Project Name |

Exchange Square

| |

Systems |

HVAC - Waterside Air Conditioning System

Building Automation /Management System

Smart control Platform

| |

Building Types |

Commercial - Office

|

Description of the building:

|

|

- Grade A Commercial Buildings for a prestigious, globally oriented, 24-hour business complex.

- 52 levels for One Exchange Square and 51 levels for Two Exchange Square comprising of offices, retail, and F&B outlets.

- Fully air-conditioned with direct sea water-cooled central chilled water system with primary and secondary chilled water pumping system.

- Air handling unit (AHU) and Fan-coil units (FCU) for offices, retail, and F&B outlets with pre-treated fresh air.

Retrofitted initiative:

- Centralised chilled water plant:

Two 3,000Tons existing sea water-cooled chillers were replaced by two new 1000Tons and one 2000Tons direct sea water-cooled chillers. New primary pumps were also replaced for new chillers. For Chiller-1A and 1B, two new primary pumps are installed for chilled water and two new heating water pumps were installed for heating water system. For Chiller-2, two new primary pumps were installed. At the discharge side of each chiller, constant flow control valve was installed for automatic flow rate control of chilled water passing through each chiller. A decoupling chilled water system was arranged for the central chiller plant. It consists of constant water flow through each chiller evaporator and variable flow secondary water distribution system.

- Chilled water plant control:

DDC control system is provided for fully automatic control, energy optimisation control, monitoring, supervision and data logging for chilled water plant operation. The building load requirement is predicted by the DDC control system based on the loading profile in the past years. The predicted building load is analysed to determine the optimum configuration of the chiller plant.

- Implementation of JEDI (Jardine Engineering Digital Insight):

This further enables system fault detection, chiller optimisation and real-time energy dashboards.

|

|

|

Observed benefits other than energy saving:

- Lower noise level since the new chillers adapt multiple stage of compression which operate exceptionally quieter.

- Heat recovery at condenser side of chiller to eliminate additional heating equipment and reduce condensing water (seawater) provision.

- Diversity in chiller capacity and chiller types to cater for optimisation based on cooling loading.

- Enhanced building load prediction system with optimised control logic to allow the system to determine the most optimal combination of equipment to suit the predicted building demand.

General observations of the retrofitting project:

- Before the project, heating water was generated by the old chiller which can either operate in cooling mode or heating mode. We applied heat recovery operation in this project since the buildings require simultaneous cooling and heating, i.e. the base building cooling demand is high even in winter. This is the most critical consideration to adapt this energy saving operation.

- All chiller units are now being fitted with an electromagnetic clamp-on device installed on the exterior of condensing seawater pipes. This greatly hinders growth of microorganisms which adversely impact the heat transfer at the condensers.

Other information:

| Cost |

Saving |

| Total cost: |

over HKD 60 million (2016) |

Savings/year breakdown: |

>23% saving on annual water side energy consumption

>3.4 MWh saving per year compared to maintenance cost of aged chillers >HKD 6 million |

| Cost breakdown: |

Mechanical and Electrical work over HKD 15 million

Chiller Supply over HKD 30 million

Major Equipment Supply over HKD 15 million |

| Payback: |

(HKD 60 million – HKD 6 million) / HKD 4.9 million = 9.15 years |

| Name of the consultant and contractor |

Consultant:

J. Roger Preston Ltd.

Contractor:

The Jardine Engineering Corp., Ltd. |

| |

|

Replacement of more efficient chiller

Installation of smart energy management platform for data collection and visualisation, performance monitoring and evaluation, demand control and efficiency optimisation

|

|

|